By Milan Brandt

Globalization is changing the nature of business in high-wage countries with companies having access to new and diverse markets and on the other hand, facing increased competition from low-wage countries. This is driving them to seek approaches to lower their costs and increase product diversity. Manufacturing industries in Australia make a significant contribution to the economy and directly employ some 10 percent of the workforce or about one million people. These industries also drive skills development across other sectors and provide major markets for service businesses. Over the last five years these industries have been facing a number of significant challenges due to the increasing global competition and imports of relatively cheap goods from overseas mainly China. This has contributed to many companies in particular in the manufacturing states like the State of Victoria closing operations locally and moving production off-shore.

As a consequence, new funding support for manufacturing from both the federal and state governments is rising. Advanced technology, research and innovation are seen as critical elements in delivering cost-competitive approaches for manufacturing companies to survive and remain profitable in the future. Additive manufacturing (AM) is seen as one technology that could boost local manufacturing because of the many benefits it offers over traditional manufacturing. With additive technologies parts, both polymer and metal, can be built directly from computer models or from measurements of existing components to be re-engineered, and therefore bypass traditional manufacturing processes such as cutting, milling and grinding. Benefits include: 1) new designs not possible using conventional subtractive technology, 2) dramatic savings in time, materials, wastage, energy and other costs in producing new components, 3) significant reductions in environmental impact, and 4) faster time to market for products.

The funding support has resulted in new industry led research centers such as the Innovative Manufacturing Cooperative Research Center (IMCRC) a consortium of industry and research providers with government funding of AUS $40 million over seven years. Additive manufacturing is a core technology focus for the IMCRC. In addition to this, an Advanced Manufacturing Industry Growth Center Initiative was also announced. The Growth Center seeks to connect industry, research and government to deliver transformation primarily in the health, mining and energy sectors. A further announcement in December 2015 of the National Innovation and Science Agenda opened up additional funding streams to support domestic entrepreneurial activity, supporting SMEs to retrain and purchase capital items, and to the research community for maintenance of research assets, and to fund small scale research projects. This governmental support is encouraging for Australian industry to make the leap towards the adoption of additive manufacturing technology.

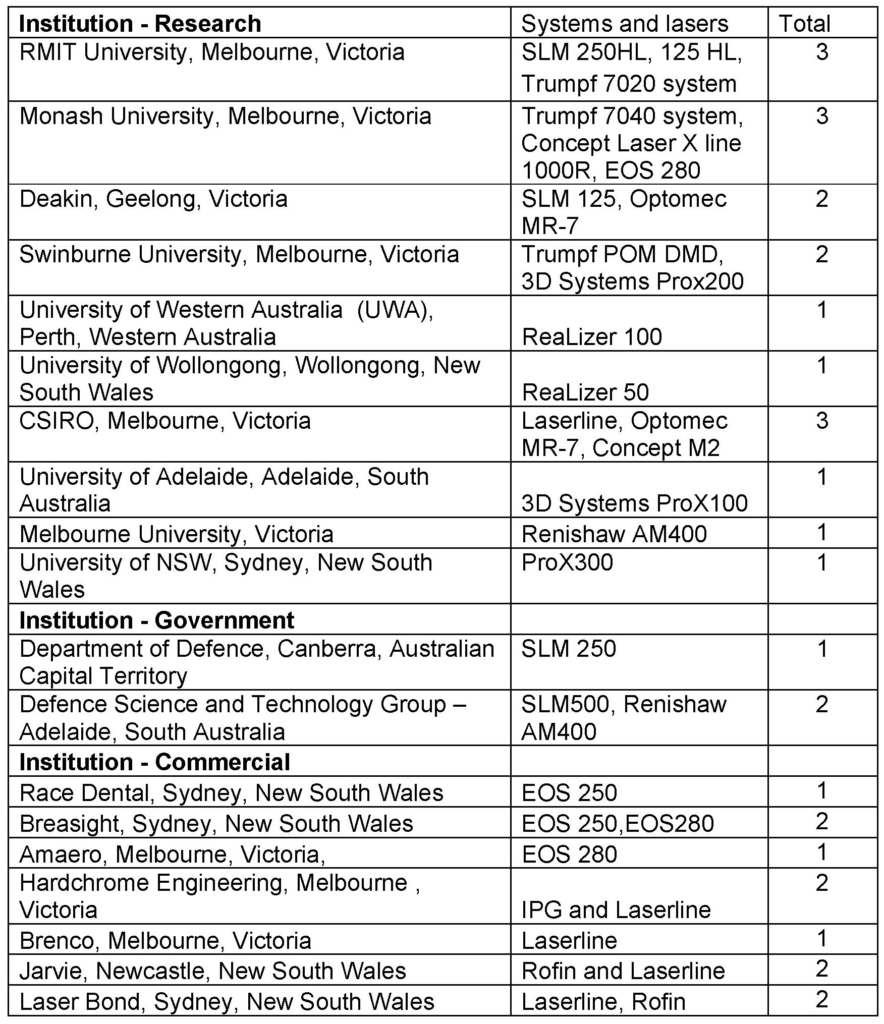

Australian industry has been aware of the laser cladding technology since early 2000 and there are four companies, Hardchrome Engineering, Melbourne Brenco, Melbourne, Jarvie Engineering, Newcastle now owned by the AEA Investors LP, the group that owns Swanson Industries and Laser Bond, Sydney, providing laser cladding services to the mining, manufacturing and power industries. The adoption of the other laser additive technology, Selective Laser Melting (SLM) is increasing in both the research sector and industry. Since 2011, there have been a number of new laser research facilities established predominantly in the State of Victoria. The new facilities involve TRUMPF, EOS, Concept, Optomec and Renishaw Laser. A list of organizations with laser additive technology and their location in 2016 is shown in Table 1. These systems will certainly play a major role in the future helping local industry better understand the issues and capabilities associated with metal AM technology.

Australian Research & Development Activities in Laser AM

The number of researchers and research organizations entering the AM area in Australia is growing. The two largest research groups engaged full-time in the research and development of both new additive applications and laser materials processing in general are the RMIT Center for Additive Manufacturing based at the RMIT Advanced Manufacturing Precinct (AMP) shown in Figure 1 and the Monash Center for Additive Manufacturing at Monash University. The groups complement each other and have informal collaborations. The RMIT Advanced Manufacturing Precinct is a $25 million dollar research and teaching facility opened at the end of 2011 to assist local manufacturing industry to compete in global manufacturing markets and train the next generation of engineering graduates in AM technology and concepts.

a)

b)

c)

The Precinct’s overall aim is to enhance and develop new sustainable products and skills using state-of-the-art equipment and manufacturing techniques. It brings together research design and advanced manufacturing in one location, opening the doors to new opportunities for innovation and product development, prototyping, rapid and additive manufacturing for the advanced manufacturing industry. It also provides a vital hub for RMIT’s industry engagement, which revolves around multiple industry sectors and areas of strength. The additive manufacturing equipment at the Precinct includes the latest in both polymer and laser based additive technologies and represents a one-stop shop for companies interested in exploring and developing new products based on additive technology.

RMIT Center for Additive Manufacturing was formed in 2014 to be a leading provider of research and development in digital additive manufacturing to Australian corporations and SMEs focusing on global markets and manufacturing supply chains. The Center has two research themes, Design and Manufacturing and Materials focusing on developing software tools for AM and new manufacturing and materials processes. The targeted industries are aerospace, biomedical, defense and mining. An example of the Center research is an aero component made from Ti64 which was topologically optimized for additive manufacture as shown in Figure 2. This project was supported by the Defense Materials Technology Center and involved Defense Science and Technology Group and Lockheed Martin and was focused on the manufacture and design consolidation of relatively small components with complex, high-value, high-cost integrated structures found on the JSF.

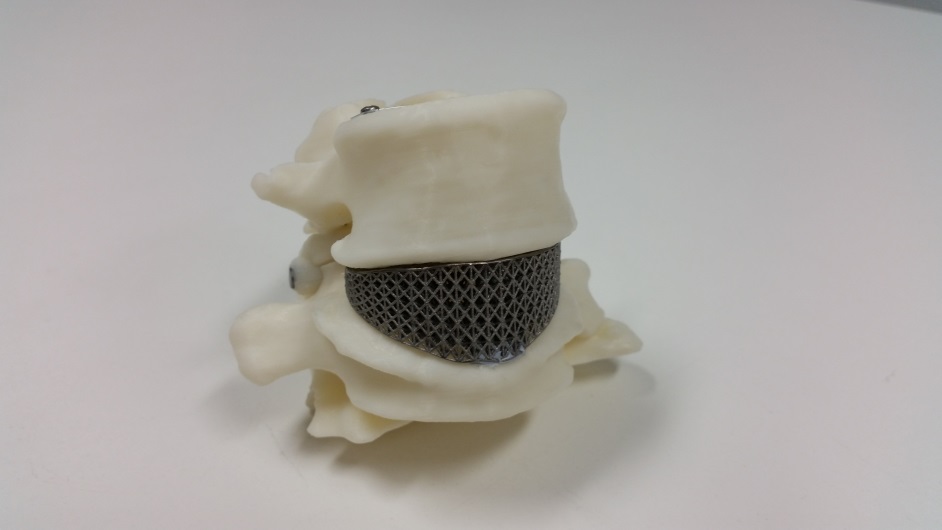

In another recent project with local medical device company, Anatomics and spine surgery specialist Dr. Marc Couglan the Center successfully create Australia’s first 3D printed vertebral cage titanium implant for a patient with severe back pain. The technology used to design the special lattice structure required for implant is based on the Center developed design tools. Shown in Figure 3 is the implant together with an example of a lattice based implant in a model bone being developed in collaboration with Prof. Peter Choong, an orthopaedic surgeon focusing on osteosarcoma bone cancers.

a)

b)

The Monash Center for Additive Manufacture takes fundamental research in material science, alloy design and processing and applies it to laser additive manufacture of parts and components. The focus is very much the aerospace industry and the Center has attracted overseas and local organizations as partners. The Center spun-off a company, Amaero Engineering in 2013 which specializes in the manufacture of metallic components by both SLM and laser metal deposition techniques. Some of the aero components it manufactured from a nickel alloy are shown in Figure 4.

a)

b)

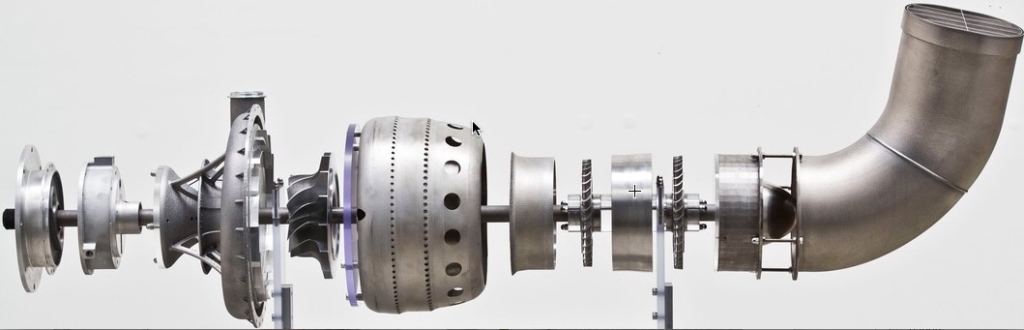

Shown in Figure 5 is a model of a jet engine that the Center has been working on with Microturbo, a member of the Safran group, and CSIRO involving high temperature alloys.

Laser additive manufacture in Australia is seeing growth and diversification and this trend will continue, driven by several factors such as the need for local companies to diversify their operations and move away from high-cost, labor intensive manufacture, better industry awareness of the laser additive technology’s capabilities, and increased trend by their overseas competitors exploring this technology. The R&D base in the area has also expanded significantly in the last few years and the establishment of a national program on additive manufacturing through the Innovative Manufacturing CRC will further accelerate this growth as the industry partners become more familiar with and adopt laser and other additive manufacturing technologies in their operations.

Milan Brandt is the Professor of Advanced Manufacturing and Director of Advanced Manufacturing Precinct and Centre for Additive Manufacturing.